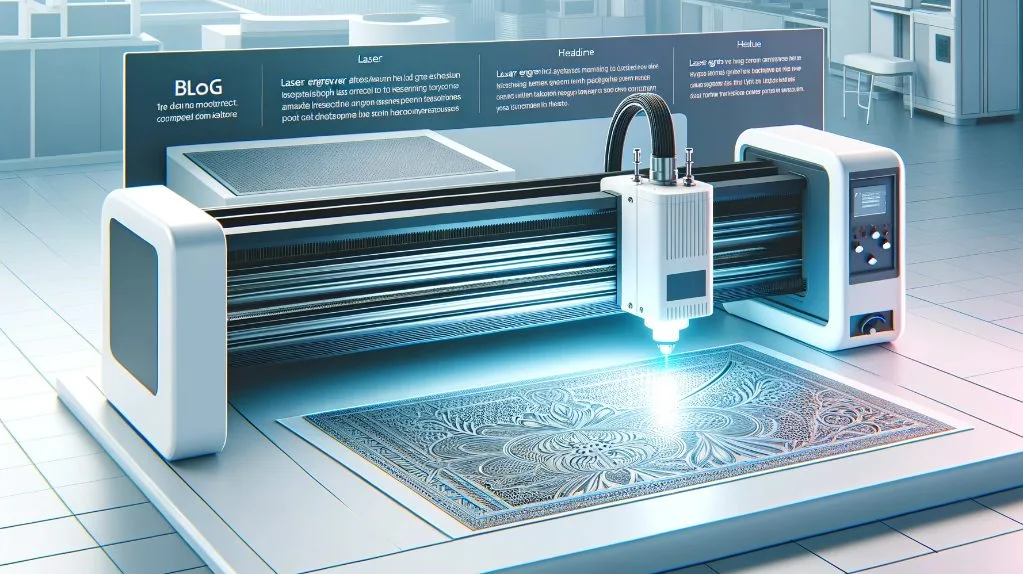

Laser engravers are incredible tools for precision and creativity in various applications, from crafting intricate designs on materials to personalizing items with precision. However, laser engravers require regular maintenance, like any other equipmentfr, to ensure they function at their best. Creating a routine for your engraving machine to regularly check it for issues and clean and maintain it is ideal. This comprehensive guide will walk you through cleaning and maintaining your laser engraver to guarantee optimal performance and pro health longevity.

Understanding The Basics

Before diving into the cleaning process, it is crucial to have a basic understanding of how a laser engraver works. Laser engravers use a focused laser beam to remove material, leaving a design or pattern behind, depending on what you want to achieve. The precision of the machine relies on the cleanliness of its components, which is why it is vital to ensure you clean and maintain it regularly. .

Safety First

Before you start the maintenance process, ensure your laser engraver is powered off and unplugged to reduce the chance of a workplace injury. Safety goggles are a must to protect your eyes from potential laser reflections. Additionally, use a pair of gloves to shield your hands from cleaning agents and dust.

Cleaning The Lens

The lens is a critical component of your engraving laser machine, as it focuses the laser beam onto the material. Over time, dust and debris can accumulate on the lens, affecting the quality of engravings, so you will want to clean it. To clean the lens:

- Remove The Lens: Consult your engraver’s manual to understand how to remove the lens safely.

- Use Compressed Air: Gently blow away any loose particles with a can of compressed air. Hold the lens carefully to avoid any damage.

- Lens Cleaning Solution: Apply a small amount of a dedicated lens cleaning solution to a lens cleaning tissue. Wipe the lens gently in a circular motion, avoiding excessive pressure.

- Inspect For Residue: Inspect the lens for any residue after cleaning. If necessary, repeat the process until the lens is clear.

Cleaning The Ventilation System

The ventilation system is crucial for dissipating heat generated during the engraving process. Over time, dust and debris can clog the ventilation, leading to overheating issues. Follow these steps to clean the ventilation system:

- Power Off The Laser Engraver: Ensure the machine is powered off and unplugged before cleaning it.

- Remove The Cover: Refer to your engraver’s manual to remove the cover get safely and access the ventilation system.

- Use Compressed Air: Blow out any dust or debris from the ventilation system using compressed air. Pay special attention to fans and vents.

- Inspect & Replace Filters: If your engraver has air filters, inspect them for dirt and replace them if necessary. Clean reusable filters according to the manufacturer’s instructions.

Cleaning The Rails & Bearings

The rails and bearings of your laser engraver facilitate smooth movement of the laser head. Regular cleaning is essential to prevent friction and ensure precise engraving. Follow these steps to clean and maintain the rails and bearings of your engraving machine:

- Wipe With A Clean Cloth: Use a clean, dry cloth to wipe the rails and bearings. Remove any accumulated dust or debris.

- Apply Lubricant: Apply a small amount of lubricant specifically designed for your engraver’s rails and bearings. Refer to the manual for the recommended type and quantity.

- Move The Laser Head: Manually move the laser head along the rails to distribute the lubricant evenly.

Calibration Check

It’s essential to periodically check and recalibrate your laser engraver to maintain accuracy in your engravings. Calibration ensures that the laser beam follows the intended path with legion precision. Refer to your engraver’s manual for specific calibration instructions, and you will want to check the calibration of your engraving machine regularly, to ensure nothing changes.

Regular Software Updates

Keep your engraving software up to date by installing the latest updates the manufacturer provides. Software updates often include improvements, bug fixes, and new features that contribute to the overall performance of your laser engraver. Get into the habit of checking for updates regularly to ensure you get the latest updates as soon as they are available.

Regular cleaning and maintenance are how you get a long-lasting, high-performing laser engraver. Following the steps outlined in this guide, you can ensure that your machine remains in optimal condition, producing crisp and accurate engravings for many years. Ensure that you consult your engraver’s manual for specific instructions tailored to your machine, and always prioritise safety throughout the maintenance process. With a well-maintained laser engraver, you will continue to unlock endless possibilities for creative and precise projects. A well-maintained machine will also help ensure that you do a fantastic job for every one of your customers and enhance your overall reputation.